Surface treatment is a kind of processing method which uses grinding machine, polishing machine, calender and other machinery to reduce the surface roughness of the blank, so as to obtain a bright and flat surface.We mainly have mirror polishing, electrolytic polishing, roller polishing and so on.

During mechanical polishing, the high-speed of rotating polishing wheel (circumferential speed above 20 m/s) presses the workpiece, so that the abrasive can roll and micro-cut the surface of the workpiece to obtain a bright surface. The surface roughness can generally reach Ra0. 63 ~ 0.01 microns.

When the barrel polishing machine rotates, the steel balls and abrasives are randomly rolled and collided in the barrel to remove surface protrusions and reduce the surface roughness, which can remove 0.01 mm margin.

During precision polishing, the barrel can be rotated continuously for several hours to get a bright surface. The polishing of the precision scale is carried out by immersing the processed surface in a polishing liquid. The polishing liquid is a mixture of chromium oxide powder with a particle size of W5 to W0.5 and an emulsion. The polishing wheel is made of wood with uniform material and degreasing treatment or special fine felt. The track of movement is a uniform and dense mesh. The roughness of the surface after polishing is not bigger than Ra0.01 micron. Under a microscope with a magnification of 40 times. There are no surface defects. We also have mirror polishing.

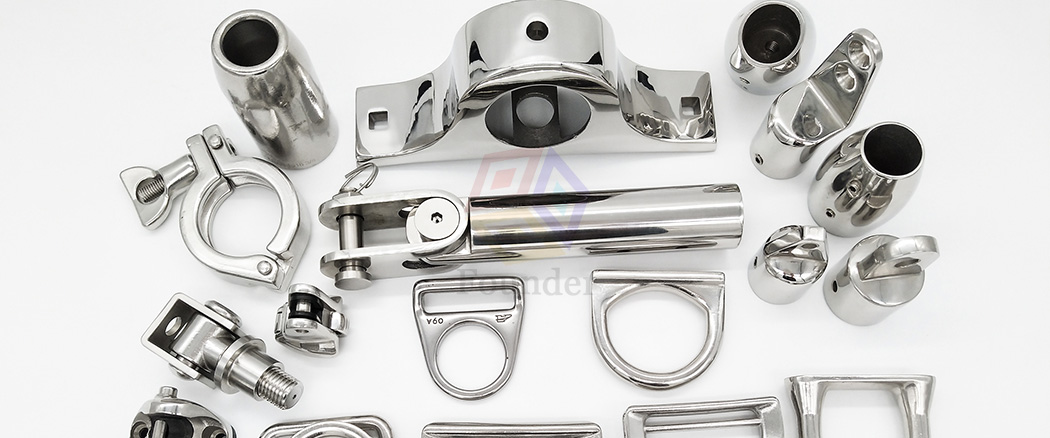

The surface of our rigging hardware, marine hardware, pipe fitting, and car accessories are basically mirror polished, barrel polished, electronic polished or acid washed